The Art of Nail Manufacturing: A Guide to Building Strong Structures

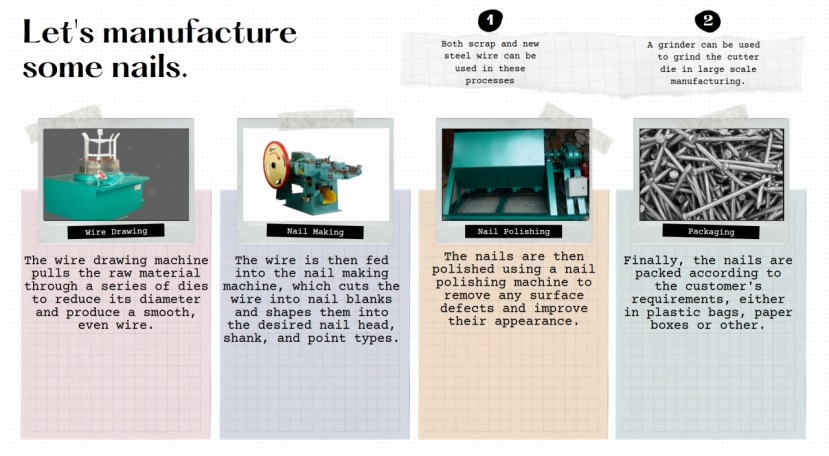

In this article let’s take a look at the nail making machine along with its full production line, which includes:

- The wire drawing machine, which is used to draw the wire to correct diameter.

- The actual nail making machine, used to make the nails.

- Nail polishing machine, to make the nails visually appeasing.

- A grinder to grind the cutter die in large scale manufacturing.

- Both scrap and new steel wire can be used in these processes.

Nail Specifications:

Common nails consist of a wide head, a smooth shank, and a diamond-shaped point. They come in various head, shank, and point types including circular flat, double head, diamond head, spring head, smooth shank, ring shank, screw shank, square twisted shank, diamond point, diamond point offset, and round point. The raw material for common nails is 6.5 mm diameter Q195 and Q235 carbon steel.

Production Line Requirements:

- Common nail production involves several processes: material preparation, wire drawing, nail making, polishing, and packaging.

- The production line includes a wire drawing machine, nail making machine, nail polishing machine, and packing machine.

- Different nail making machines may be required depending on the desired nail sizes (e.g., Z94-2C, Z94-4C, and Z94-5C).

- The power intake for the machines ranges from 1.5 kW to 4 kW.

- The production capacity ranges from 260 to 450 nails per minute.

- The minimum budget required for setting up a nail making factory ranges from $100 to $10,000, depending on the size of the operation.

Environmental Impact:

The environmental impact of common nail production is considered low. Both scrap and new steel wire can be used to make nails, which reduces waste and conserves resources. However, the production line may generate noise pollution and emissions from the machines. It's important for nail manufacturers to comply with local environmental regulations and implement measures to reduce their impact on the environment.

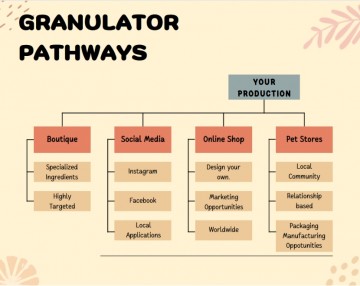

Business ideas

Nail manufacturing and distribution: Produce and distribute common nails in various sizes and types to construction companies, hardware stores, and other businesses that require nails.

Private label nail production: Create customized nails with unique branding for other businesses such as hardware stores, home improvement retailers, or construction companies.

Nail packaging and labeling services: Provide custom packaging and labeling services to other nail manufacturers or businesses that require specific branding and packaging for their products.

Nail export business: Export common nails to other countries where there is a high demand for construction materials and hardware products.