Money on paper: Paper Cups Production

Industrialization No w

where the money is?

Start with less than 10,000$

Where the money is!

New niche products and changing technology are opening up whole new manufacturing business ideas for startups. From meal kits to non-plastic packaging, consumer demand is creating exciting opportunities for enterprising manufacturers.

Before investing in a business, check out local demand for your production, typical pricing as well as competition to be sure that you can create a profitable business model. Your chances of success will increase if you can get one of your potential customers to act as a mentor who will help you fine-tune your business plan for your market.

Here I’m going to walk you through some brilliant and affordable ideas for making money really quick, with ROI less than 6- month if executed properly, get your hands dirty NOW, for more details never hesitate to contact the writer aibo@kichuguu.com

Money on papers!

- Food-Kit Packaging (Bio-degradable packaging)

- Branded Paper Cup (coffee cups)

- Paper plates

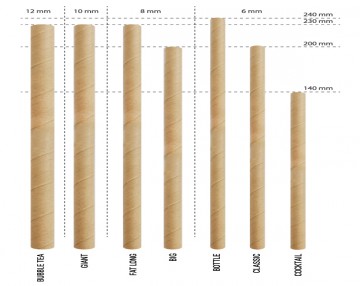

- Paper Straws

- Napkins and Tissue paper

- Paper bags

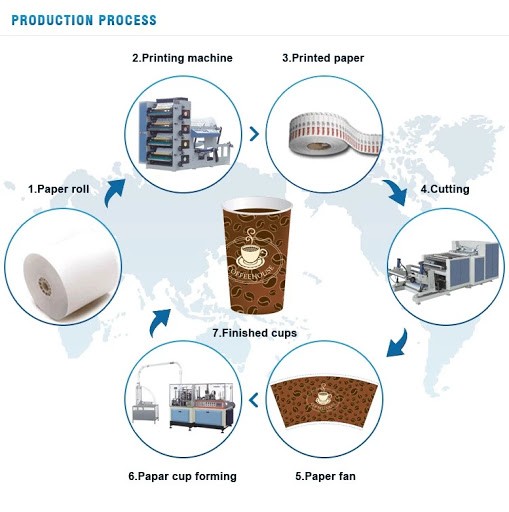

Paper Cup Manufacturing

Food and Drinks business ideas never go out of style as everybody needs to eat and drink, several times a day. That’s why starting a business centered on food can be a truly rewarding enterprise. Food cooked or raw need to be packed, and presented in a good clean way!. Here we will present simple business plan and insight for paper cup factory.

Machine needed

The paper cup forming machine passes automatic paper feeding, cup wall sealing, cup bottom punch and insert to cup wall ,bottom pre-heating, main heating, bottom knurling, top curling, discharging and collecting.It is an ideal equipment of making paper cups for hot or cold drinks (coffee, tea, ice cream, juice, beer, soup, food , snacks, etc).

click to see the video https://youtu.be/Eg2iK7R5h2c

Optimal output

For profitable business model, we recommend you look for machine output of at least 50,000 standard cups per day (that is 60 cups per minutes); price start at 6500 USD, you can start this business with 10K, that plus starting raw material and set up cost.

Raw material needed

Supported Cup Dimension:

Top Diameter: min 45--max 110mm

Bottom Diameter: min 35--max 80mm

Height: Minimum 40mm---Maximum 130mm

Simply saying a cup holds 3-12 oz (matter of fact you can make different sizes with different molds)

raw Material: 1. PE coated paper reel (For cup bottom)

2. Die cutting paper (For cup body)

For cold drink recommend to use PE coated paper for both cup body and bottom

The machine Dimension is 2500 by 12000 by 1400, pretty handy to fit in your extended backyard or a small godown facility, the machine use 4.5 KW of power at 3-phase power line.

Standard cup use 170-420 gsm, single or double PE coated paper, and please be noted for this proposal, you will need to buy “die cut” paper, already cut and printed for the cup body, the machine only weld the cup body to bottom.

Product Price: Standard paper cup: about 0.015$/Pc (minimized)

per day production: 50,000units (assume 5 gram per cup)

Sales per day : 1,000 USD

Material cost: 1500$ (DDP most major port) per ton (average cost for PE coated and uncoated)

material per day cost: 0.3 x 1500 = 450$ (maximized)

Production cost: assume 20% of sales = 200$ (Max)

Minimum Profit: 1000 - 450 -200 = 350 USD

That about 2,400 USD per week or 10,000USD per Month!

Learn more about this machine

https://www.kichuguu.com/machine-details/paper-cup