Cupcake Production Line

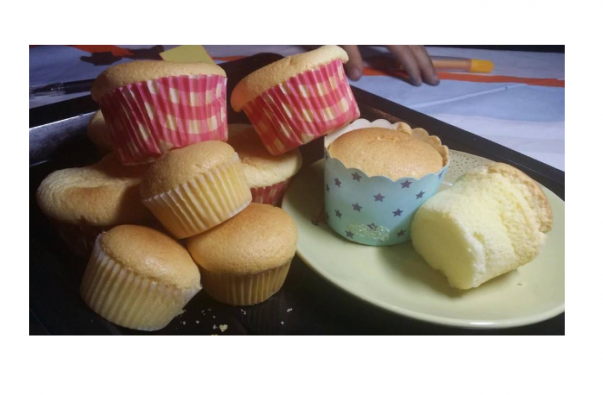

Cupcake Production Line serves for the purpose of making cupcakes as well as average cakes, European-style cakes and other styles of cakes of various sizes. The line can be set at the range of 10g-100g at customer’s request and is known for rationalized structure, easy and smooth operation, and high efficiency. Using advanced technologies and controlled by computer programs, the system is widely welcome among food producers. Please find more information about the production precedures below:

20L Planetary Mixer is as the largest machine it can hold up to 5 kg per mix. ideal for bakers or chefs working on a big scale. With compact structure, the machine is operated conveniently. It is safe and hygienic for its transmission mechanism is sealed inside the machine. The machine is settled three grade: fast, middle and slow, It is the ideal facilities to made high-grade bread and cake.

Cupcake Making Machine can be used for a variety of cakes, pastries , pastry products , structure simple and reasonable, simple operation, easy to adjust , easy disassembly and cleaning. The injection feed rate can be adjusted with high precision injection material , the maximum injection feeding amount up to 1000 ml. The device with different discharge head can fit the needs of various occasions and products ; with injection needles stuffing , stuffing can be injestion in breads and cakes,can customized heads to injestion different bread.Important power is air compressor. Machine material contact parts are made of stainless steel 304 and PTFE (polytetrafluoroethylene , commonly known as " plastic" ). It is consistent with national food safety requirements. Such equipment is particularly suitable for small product yield varieties of small and medium food enterprises , cake room , bakery , small workshops and just entrepreneurial individual producers.

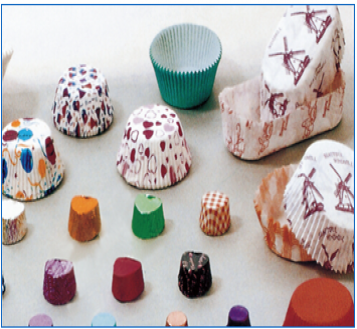

Cake Paper Cups Forming Machine uses machine hand to clip paper, feeding paper, separate paper, punching, discharge etc. This model can make different size of cake tray through changing mould. Simple structure, inverter, auto temperature controller, easy to operate, high efficient and stable running. Max round paper diameter for the paper tray is 150mm, and the max square paper diameter is 130mm. Generally, the raw material is 15-110gsm greaseproof paper. The capacity is 15-30pcs/time 20-40times/min. 2.5KW as it is low power and can make various types of paper cups for cupcakes.

The use of the Rotary Oven in and out of the operating mode, each baking 32times, easy operate, time-saving and labor-saving. The stainless steel electric heating tube and the original imported burning machine can save the energy consumption while ensuring the quality of use. The use of super thick health insulation materials,reduce energy waste,energy consumption will be reduced to a minimum. Customers can be based on their own internal energy to choose according to:rotation power type,diesel type,gas type,easy to rotate,to maximize the use of energy. Uniformity:strong wind convection,good penetrability,more uniform.

- Country

- :

- China