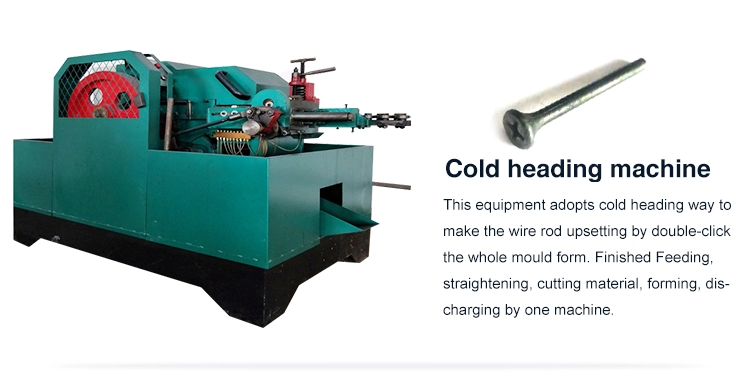

Automatic steel nail manufacturing machine / screw nail production line

This production line is used for making drywall screws. It include Cold Heading Machine, Thread Rolling Machine. Adopts cold heading way to make the wire rod upsetting by double-click the whole mould form. Finished Feeding, straightening, cutting material, forming, discharging by one machine.

Process

Wire-Rod → Wires-Drawing → Nail-Making → Polishing → Packing

Characteristics

1) High Speed

2) Low Noise

3) Less Impact

4) Good Continuity

5) Main components are made of quality steel, such as shaft, cams and gear.

6) It adopts plunger and oil pipe lubricating structure.

7) It can make the high quality of asphalt felt nails and other special nails used for high speed coil nail welder and coil nailers.

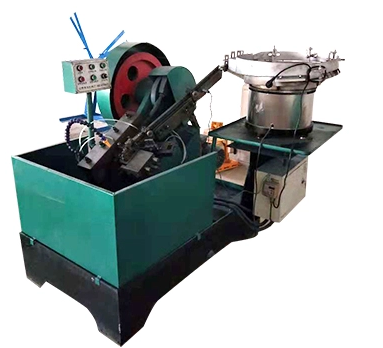

First step: wire drawing machine is used to draw the wire to the fine dia we need. Also make all kinds of pulley wire drawing machine

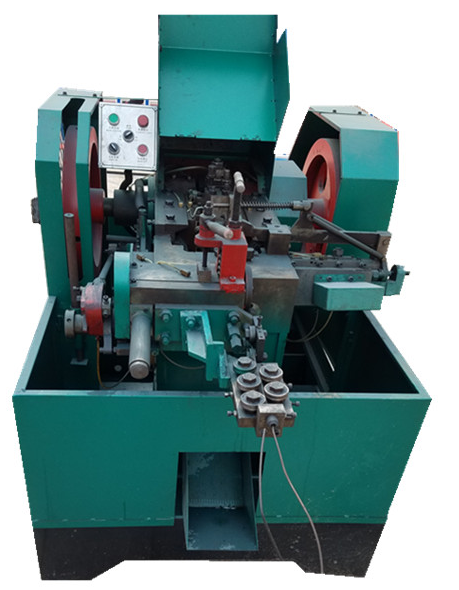

Second step: nail making machine is used to make nails. we just need to put the fine dia wire into the entrance of the nail making machine. It will finish nail making fully automatic.

Third step: nail polihsing machine is used to make the nail brighening.

Fourth step:Thread Rolling, when the work piece feed between twoplates, movable plate move forward twist workpiece, make its surface plastic deformation intothread

Product Information Details: