PP EXTRUDER MACHINE (WITH REWINDER)

It is very important to be clear of your investment, this is the soul of PP woven bag manufacturing; thing to consider

- Production capacity

- Are you going to use recycled material?

- Elecrical cost

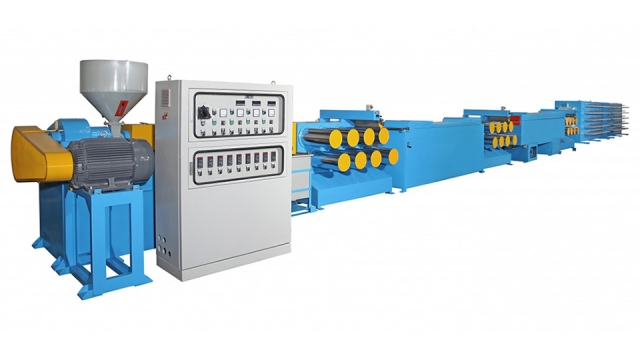

There are two common type of extruders for PP, The "stingler type, some people call germany or Austria type; The other type is "chinese" type....

The Germany type advantages are (they come in different types(single, series, magnetic etc.. and sizes )

- very fast (up to 3 tons an hour)

- accurate denier (denier can be set on control unit)

- digital controlled

- Low energy consumption

Disadvantage

- relative difficulty to install

- Almost imposible to use recycled material

- Very expensive

The Chinese Type advantages are (they come in different types(single, series, magnetic etc.. and sizes )

The Chinese Type advantages are (they come in different types(single, series, magnetic etc.. and sizes )

- Very cheap price

- Can use any type of material, matter of fact, with good technician even a mixture of recycled PET and PP can run on this type

- Relatively easy to install

Disadvantes

- Very slow ( some series only 1 ton per day)

- Most are manual controlled

- Denier set up requires series of trial and error technics

- relatively high energy consumption

looming machine (Circular weaving machines)

You will require multiple of this, standard size pp woven bag factory accomodate about 18 sets. (search flat loom for comparison)

things to consider

- The maximum width of the product you want to make

- The production speed (consider your extruder as well)

- The very high speed and expensive ones are not so suitable with recycled material

- Doesn't real matter number of shutters (six-shutter is more common in Africa)

CUTTING AND SEWING

We recomend you go for automatic cutting and sewing machine, also you will need to regular sewing machine to sew on top of the bag when require

ask for rough (zig-zag) knife on the cutter

Printing Machine

choose printer according to required quality of prints and frequency of use

if you want very good quality and requirement for printed bag is big or need two side print go for continous roll to roll printer (image two)

Other need secondary machinery are bale pressing, chillers for cooling water and mechanics tool boxes

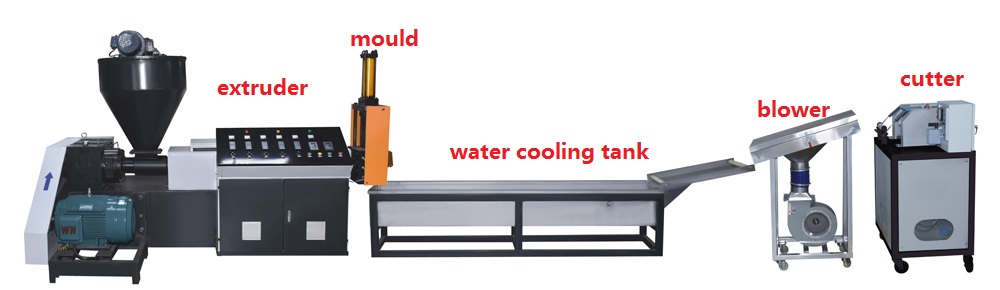

Small Recycling plant (for big industrial search PP recycle on home page)

wether you are using the recycled material or not, you will need recycle plant because during production there will some waste and you will need to granulate them

you will need a crusher (ask for big system if you are using chinese extruder, waste is slight more about 5-10% of material end up as waste during start-up)