Complete waste tire recycling production line

Functions of waste tire recycling production line:

Waste tire recycling production line/plant tire recycling machine is to grind the waste tire into rubber powder without any wire steels and fiber nylon.

Advantages: no sewage and waste gas discharge, environment protection, saving 1/3 energy.

Technical data of waste tire recycling production line:

| Model | Capacity | Drum diameter | Drum length | Front roll linear | Roll speed ratio | Max roller spacing | Motor power |

| XKP-350 | 3ton | 300mm | 500mm | 26.2m/min | 1:2.5 | 8mm | 30kw |

| XKP-400 | 6ton | 400mm | 600mm | 34.5m/min | 1:2.5 | 8mm | 45kw |

| XKP-450 | 8ton | 450mm | 760mm | 38.0m/min | 1:2.5 | 8mm | 55kw |

| XKP-560 | 10ton | 560mm | 800mm | 38.6m/min | 1:2.5 | 8mm | 75kw |

| XKP-560D | 20ton | 560mm | 1000mm | 42.5m/min | 1:2.5 | 8mm | 132kw/160kw |

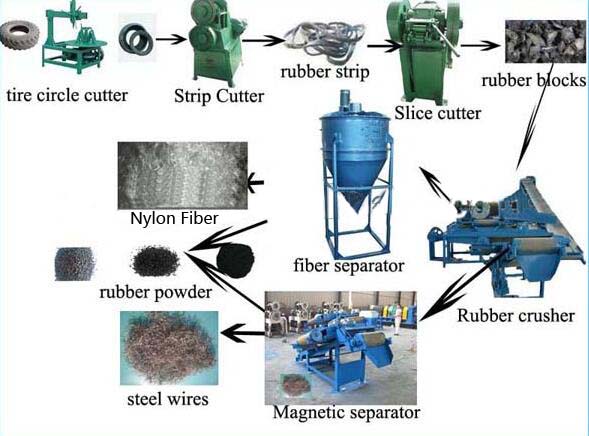

Flow process of waste tire recycling production line:

Waste tire---Tire circle cutting---Rims separating---Tire strip cutting---Tire slice cutting---Rubber crushing--- magnetic separating ---Rubber powder

First setep: Tire circle cutter is used to cut and open the joint of tire's side and top.

Second step: Rims separator is used to separate the steel rims around the tire to avoid the harm to the machine.

Third step: Tire strip cutter is used to cut the tire cirlce into strips 5x8 cm.

Forth step: Tire slice cutter is used to cut the strips into small chunks about 3.5 cubic centimeter.

Fifth Step: Rubber crusher is used to grind the chunks into smaller mesh powder through the vibrating screen as you need.

The rollers on the tire crusher: 2 grooved rollers to make sure the large capacity; material used to make roller is alloy 5CrMnMo, no need to change forever.

Last step: Magnetic separator: to separate the rubber powder from the wire steel.

Final products: Rubber powder in 5-40 mesh:

Application: the powder can be used in many fields, like making rubber tiles, the filler of the lawn, waterproof material and so on.