Product Description

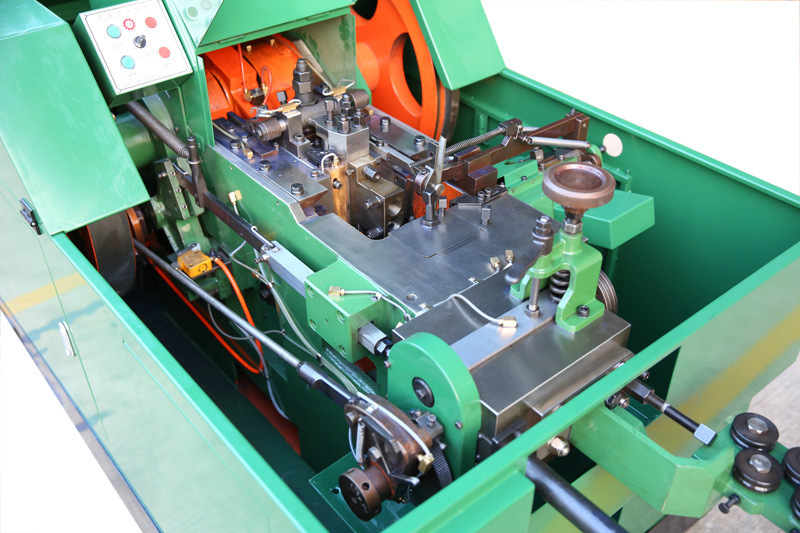

This production line is specially supplied for cold heading bearing steel, carbon steel, stainless steel, copper, aluminum etc metal ball billet. Whole working process, such as feeding, cutting, cold heading and ejection processes are automatically and continuously.

Features of screw making machine

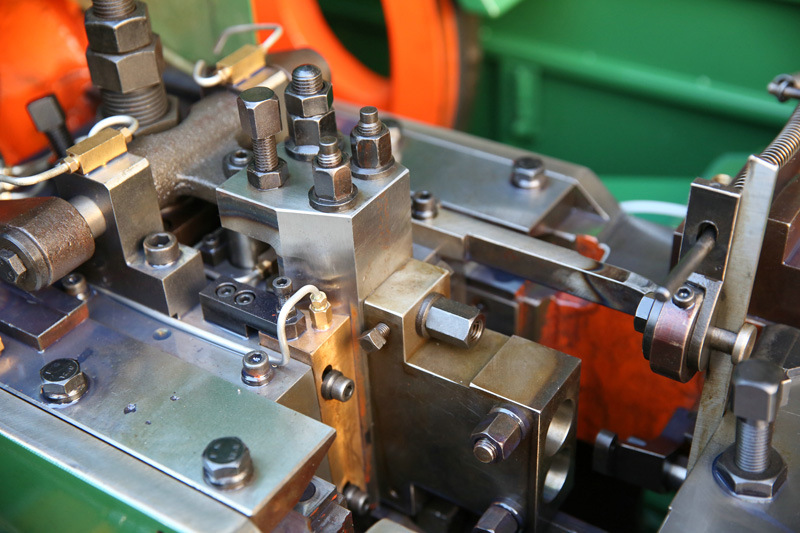

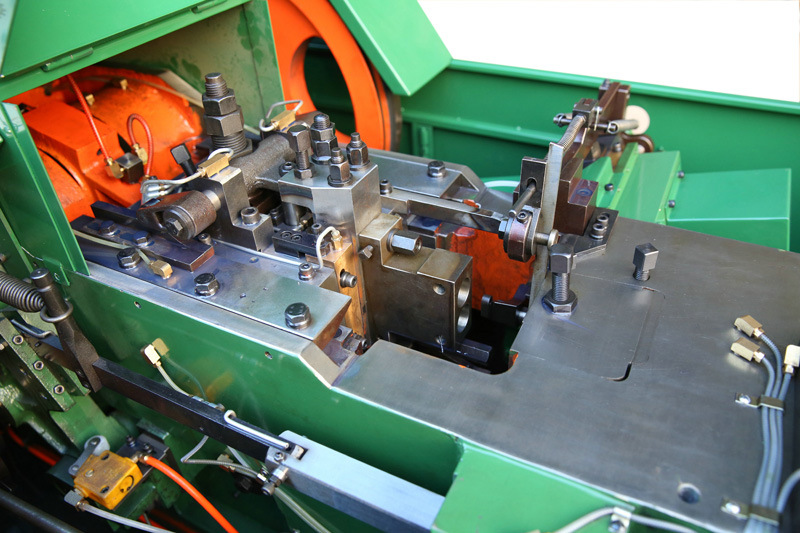

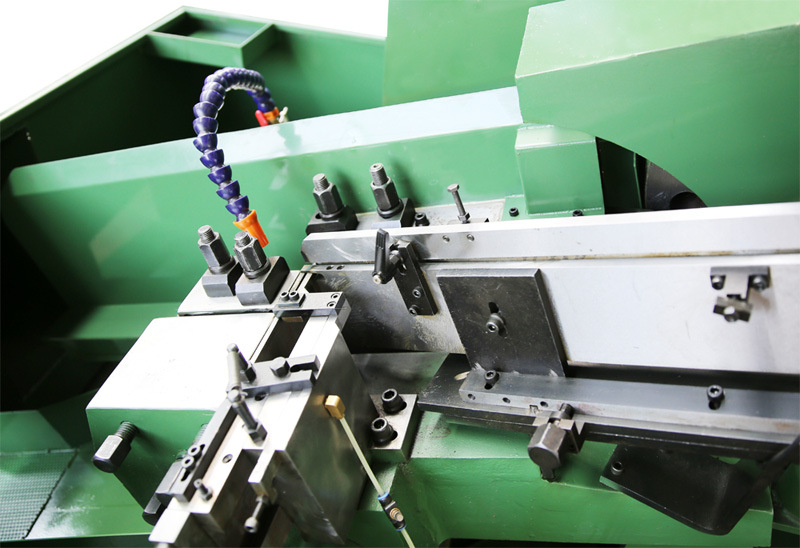

1. These cold heading machines are fully automatic and easy to operate with little training, fitted with Solid Die to produce blank for Bolts, Screws, Rivets and other similar components. Cut off and knock out mechanism have safely devices that will stop any major accident if any abnormal function occurs in machines.

2. A positive knock out provision had been made on the 1st and 2nd punches to eliminate the possibility of parts sticking to these punches during the operations.

3. On some extra charges machines will be equipped with Pneumatic Clutch & Automatic Centralized Lubrications systems which provides sufficient quantity lubricating to all bearing surface.

Head screw machine

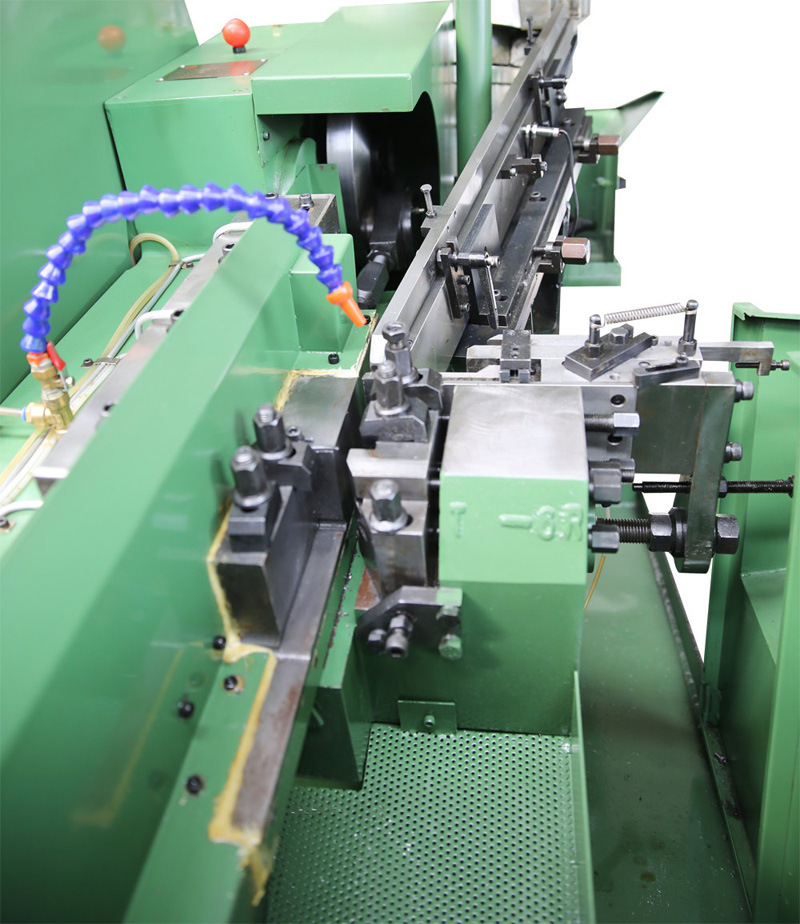

Teeth thread machine

Heat treatment furnace

Our Services

1). Any inquires will be replied within HALF DAY.

2). Before-sale and after-sale service, overseas engineer service is available.

All products have been strictly quality test in our factory before packing.

3). Free technical training, until customers can operate independently and qualified nail production produced.

4). Guarantee time: one year since machine was at buyer's factory but within 18 months against B/L date.

5). We can ASSIGN our best technician to buyer's factory for installation, debugging and training.

6).Customer who buy our nail machine can enjoy the subsequent improvements in technology.

7). Complete installation instructions, circuit diagram, manual operations and machine layout.