A. General description:

This automatic non-pvc soft bag iv solution fluid filling machine production line is made up of bag filling and capping. It has auto bag lifting, bag entering, ionic washing, bag delivery, filling with fixed amount and bag capping process. It’s applied to washing ,filling and capping for soft bag medical solution or other liquid and PP plastic bottles as well.

B. Equipment features:

1. Washing, filling and sealing are closely connected, thus it occupies less space. It has simple installation, easy operation and high automation.

2. It can be widely applied to various shapes of round, flat plastic bottles and bags.

3. It adopts ionic wind washing without water. When there is trouble, it will alarm and control the whole production line.

4. The line adopts PLC programmable controller, which is powerful and complete in intelligence control.

5. It adopts unique CIP and SIP, which is time-saving for washing and effective in sterilization. Time ,pressure and temperature of CIP, SIP can be easily adjusted on the touch screen by operators according to products needs.

6. Parameter setting is protective. On operation, each parameter can be seen, modified and monitored on the touch screen, it’s easy to operate. For example, you can pre-set maximum and minimum temperature to avoid man-made error.

7. Various shapes of plastic bottles can run smoothly in this machine without replacing specifications, especially for soft bag production.

Machine main part:

1. Bag handing Station

2. Bag filling station

3. Bag capping station

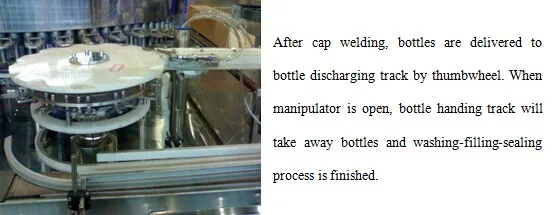

4. Bag discharging station